Motorer og generatorer til landboringer

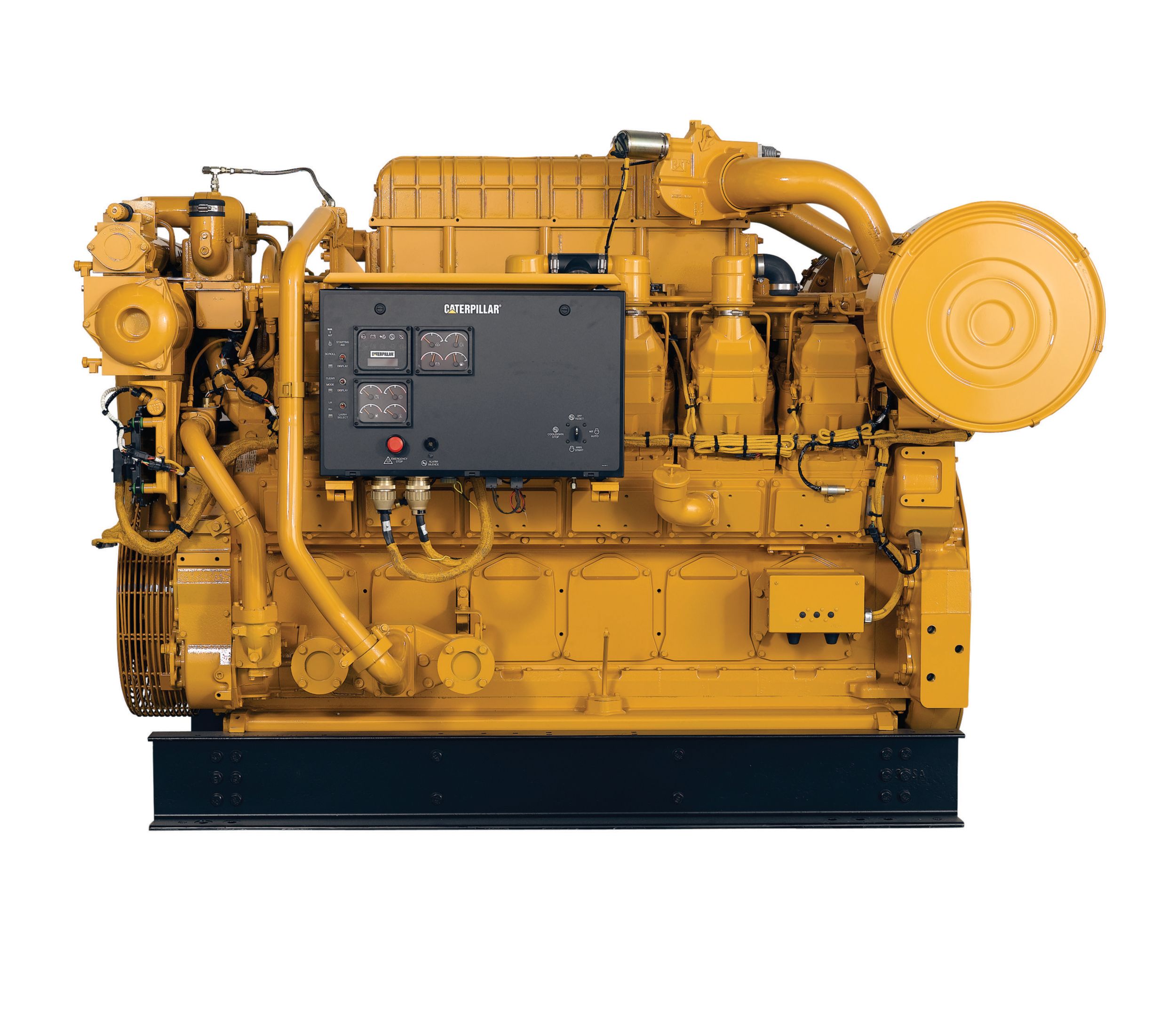

Cat 3512C

Cat 3512C (HD) motorer sætter standarden i boreindustrien. I mange år har motorer fra Caterpillars 3500 produkt-programmet været olieselskabernes foretrukne valg på grund af deres høje ydeevne, holdbarhed og pålidelighed i oliefeltet. Cat 3512C (HD) motoren anvendes primært til mekanisk drev af landbaserede borerigge. Cat 3512 (HD) motoren leverer 932-1.100 bkW ved 1.200 o/min og overholder U.S. EPA Non-road Tier 2 og CARB Tier 2 emissions-standarderne. Denne motor kan anvendes i områder som kræver U.S. EPA og EU Flexibility overholdt samt på alle ikke-regulerede markeder.

Effekt (bkW)

932-1.100

Emission

U.S. EPA Non-road Tier 2 og CARB Tier 2